TOTAL FOILS

Standart varaklarda, taşıyıcı film üzerinde toz boya vardır ve transfer işleminde bu katman karşı yüzeye aktarılır. Cilt varaklar ise, metalik olarak renklendirilmiş bir poliüretan katmanın, taşıyıcı bir filme tutturulmasından oluşmaktadır. Bu poliüretan katman tümüyle transfer yapılacak yüzeye aktarılarak kaplama işlemi yapılır. Cilt varaklar ile bir zemine uygulanmış desenli bir pat üzerine o desene uygun şekilde transfer yapılamaz, ancak yüzeyin tümü kaplanabilir. Deri ve suni deri sektörlerinde kullanılır. Ağırlıklı olarak derinin rengini değiştirmek için kullanılan cilt varaklar; güneş ışığına, aşınmaya ve terlemeye karşı dayanıklılık sağlar.

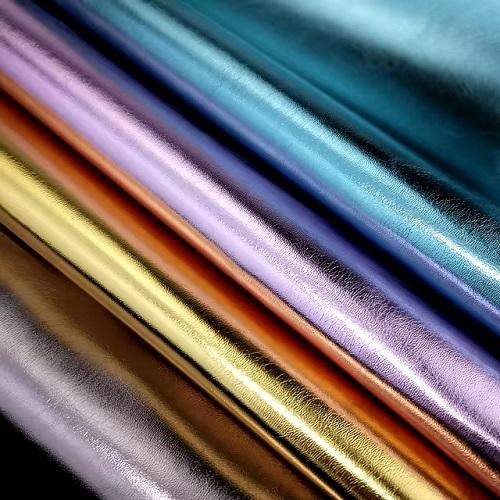

30'dan fazla farklı metalik rengin yanı sıra, altın/gümüş hologramlar ve yağ efekti cilt varaklar da mevcuttur.

Standart varaklarda, taşıyıcı film üzerinde toz boya vardır ve transfer işleminde bu katman karşı yüzeye aktarılır. Cilt varaklar ise, metalik olarak renklendirilmiş bir poliüretan katmanın, taşıyıcı bir filme tutturulmasından oluşmaktadır. Bu poliüretan katman tümüyle transfer yapılacak yüzeye aktarılarak kaplama işlemi yapılır. Cilt varaklar ile bir zemine uygulanmış desenli bir pat üzerine o desene uygun şekilde transfer yapılamaz, ancak yüzeyin tümü kaplanabilir. Deri ve suni deri sektörlerinde kullanılır. Ağırlıklı olarak derinin rengini değiştirmek için kullanılan cilt varaklar; güneş ışığına, aşınmaya ve terlemeye karşı dayanıklılık sağlar.

30'dan fazla farklı metalik rengin yanı sıra, altın/gümüş hologramlar ve yağ efekti cilt varaklar da mevcuttur.

TEMPERATURE: 120°C

PRESSURE: 6 bar

CONTACT TIME: 5-6 sec

TEMPERATURE: 145°-150°C

PRESSURE: 6 bar

SPEED: 3-5 m/min

LENGTH: 3 inch 200/500/1000 m

Customer-specific length can be produced upon request

WIDTH: 150 cm

19 micron

Direct application to synthetic leathers

Genuine leather with water based adhesives

Genuine leather with Polyurethane adhesives

Crystal foil compatibility (additional adhesive is required)

Rollercoat prints

Spray applications

Examples of Total Foil Application Areas

Shoes

The shoe industry is one of the first areas where PU foil (Total foil) is used. It can also be used as a sole or upper part of the shoe.

Bags

PU foil (Total foil) applied on genuine or artifical leather is much more shiny and vibrant than powder foil groups.

Artificial Leather

PU Foil (Total Foil) can be applied directly on PU leather and PVC leather (artificial leather) without any additional adhesive.

Genuine Leather

PU foil (Total foil) is transferred to the genuine leather as a film produced in accordance with sprayed glue base.

Chemicals Used for Total Foil Printing

Water Based Adhesives

The strenght of the PU foil (Total foil) is increased with water based adhesives used in applications on genuine leather.

Water Repellent

With water repellent layer applied under adhesive on genuine leather, the leather appearance becomes homogeneous.

Finishing Touches (Soft Hand Feeling)

Thanks to its special structure, PU foil (Total foil) is compatible with chemicals that provide slipperiness and soft hand feeling.

Application Without Adhesive

While genuine leather requires special adhesive for transfer, artificial leather does not need any adhesive.

Examples of Total Foil Printing Machines

Hand Gun

Especially in genuine leather printing process, glue is applied with a hand gun for small quantity production.

Finishing Line

Spraying finishing lines are used in high volume genuine leather printing production.

Leather Press

PU Foil (Total Foil) applications on genuine leather can be done with the help of high tonnage presses.

Rotopress

Rotopress is used for direct print without adhesive on artificial leather and for applications without cracks on genuine leather.

General Warnings about Total Foil Printing Application

This information provided on this page about foil printing is for general guidance purposes.

The details given under topics such as application areas, chemicals used for Total Foil printing and machines used for foil printing may not cover all the aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. These include foil, adhesive and the surface on which the application is made. The oil-protein balance resulting from the natural structure of the genuine leather and compatibility with the applied surface conditioning chemicals are important.

Total Foils do not have the ability to adhere to fabric or leather. However, due to the structure of the artificial leather, it is coated with a special coating that allows it to be transferred to the artificial leather with heat. The application directly affects the result if it is applied under the right conditions, such as the quality and properties of the artificial leather, printing temperature and contact time, and the activation temperature of the PU or PVC raw material.

Troubleshooting and Technical Information page is for theoretical insights into common issues.

For technical support, feel free to contact our company.

This information provided on this page about foil printing is for general guidance purposes.

The details given under topics such as application areas, chemicals used for Total Foil printing and machines used for foil printing may not cover all the aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. These include foil, adhesive and the surface on which the application is made. The oil-protein balance resulting from the natural structure of the genuine leather and compatibility with the applied surface conditioning chemicals are important.

Total Foils do not have the ability to adhere to fabric or leather. However, due to the structure of the artificial leather, it is coated with a special coating that allows it to be transferred to the artificial leather with heat. The application directly affects the result if it is applied under the right conditions, such as the quality and properties of the artificial leather, printing temperature and contact time, and the activation temperature of the PU or PVC raw material.

Troubleshooting and Technical Information page is for theoretical insights into common issues.

For technical support, feel free to contact our company.